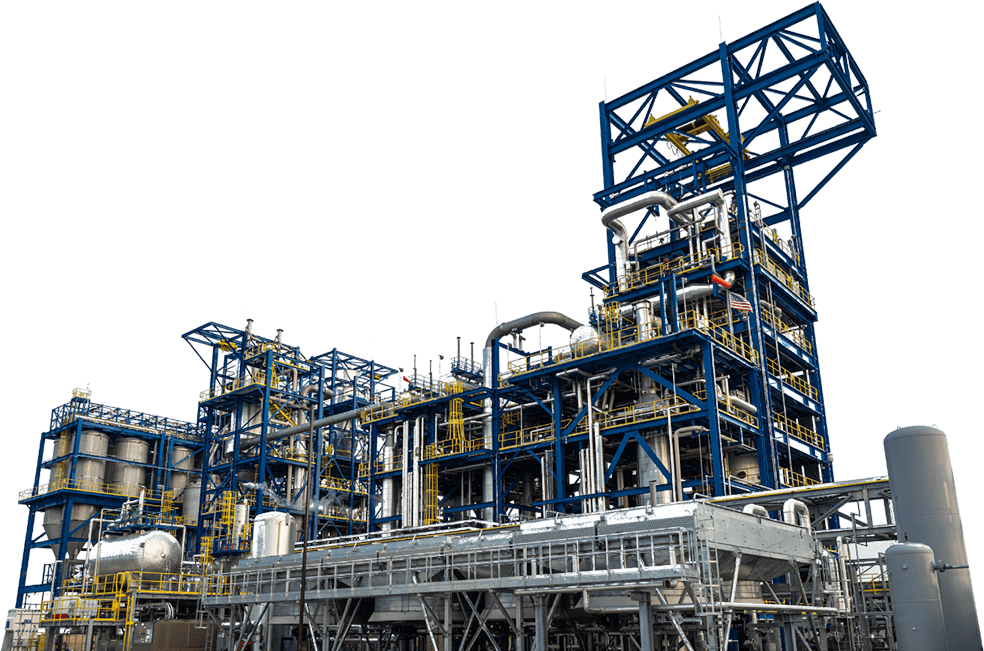

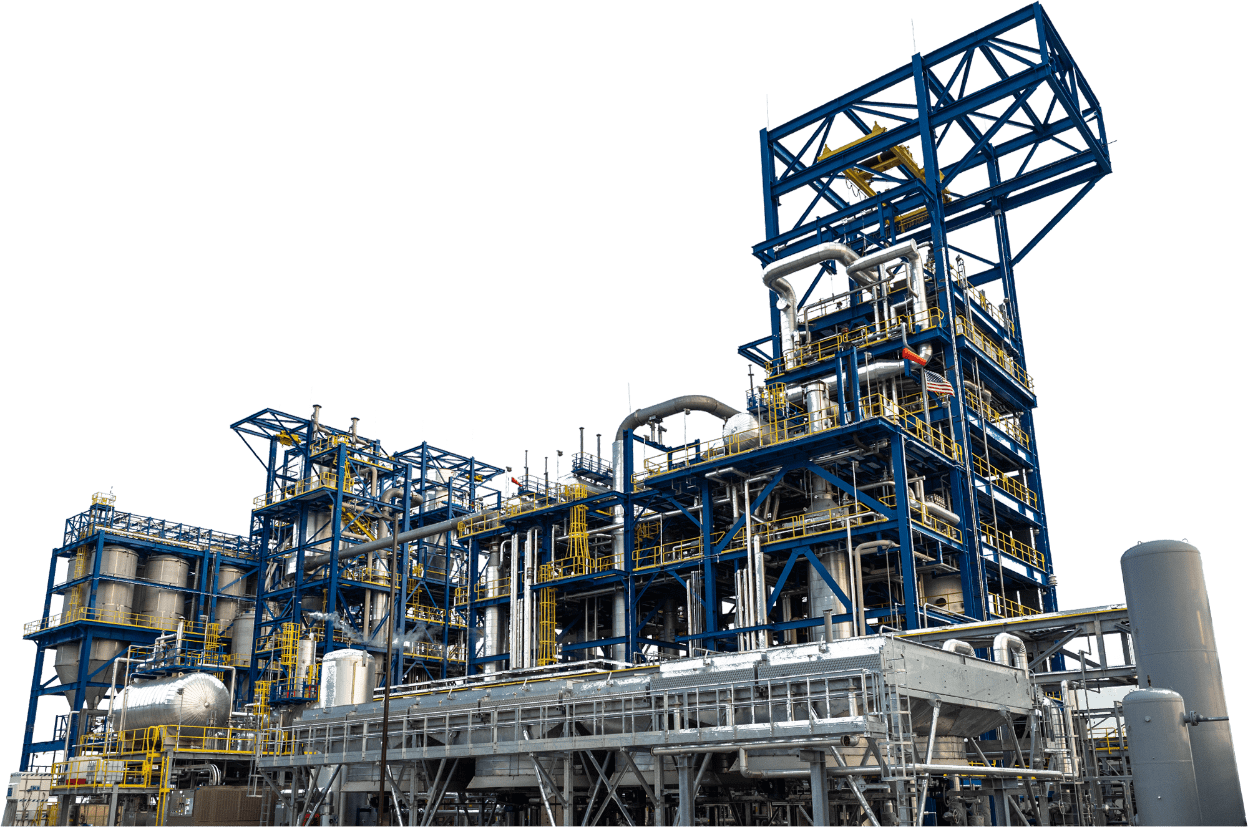

Through its proprietary technology, Monolith has innovated the thermal plasma process, a form of methane pyrolysis which harnesses electricity to create a superheated plasma that cracks the natural gas molecule into its basic elements, carbon and hydrogen. This process significantly reduces life-cycle carbon emissions from both carbon black and hydrogen production while reducing America's dependence on foreign imports.

The Monolith Process

The Monolith Process

Natural gas feedstock enters here.

A process gas can be added to help heat the natural gas.

The natural gas is superheated by electricity. This is combustion-free and CO2-free.

The heat breaks the bonds between the hydrogen and carbon in the natural gas molecule.

The pairs of hydrogen atoms and carbon atoms move through the chamber and exit separately.

From here, the hydrogen is directed to end-users. The carbon is further processed into multiple grades of high-performance carbon blacks.

The plasma advantage

The plasma process is a form of methane pyrolysis, which literally means taking the methane molecule, also known as natural gas, and heating it (“pyro”) until the molecules separate (“lysis”).

Combustion-free

No oxygen is present inside the plasma reactor. Instead, clean electricity essentially creates a constant stream of lightning that superheats the natural gas molecule and breaks it apart. There is no flame and no combustion, unlike when oil is burned in the conventional furnace process to make carbon black.

Market Driven

Monolith's innovation represents a resurgence in American-made carbon black that reduces our reliance on imports while meeting customer demands for high-performing carbon black.

Greater yield

The plasma process is even more efficient — delivering a yield of 95 percent, compared to conventional manufacturing’s 55 to 60 percent.